%402x.svg) Steel door frames

Steel door framesSteel door frames

High-Quality Steel Frames for Durability & Easy Installation

Easy installation

Manufactured in Australia

Quality materials and construction

Customisable options

High-Quality Steel Door Frames for Every Application

Fire-rated Frames

Fire-rated steel doorframes are designed to provide superior fire protection while meeting compliance requirements across various applications. Engineered for strength and durability, they seamlessly integrate with fire-rated door systems to prevent the spread of fire and smoke.

Choose your wall type, fixing method, material, and finish to ensure the perfect fit for your project. With multiple configurations available, our frames can be tailored to suit different construction needs, whether for new builds or retrofits.

Wall types

- Masonry – built in or retrofit (includes AAC block)

- Plasterboard

- Boral Eureka Wall/Hebel Wall/Powerscape Wall/Rapid

- Wall Systems/Speedwall Systems/Unipanel Wall/Askin Performance Panel

Backfilling

Most fire door frames need to be backfilled to comply with the requirements of the latest Australian standards. Based on your specific requirements, it is a good idea to check if backfill is required.

Available backfill materials include:

➢ Mortar/Cement/Grout Mixes

When afire door frame is built into a masonry brick/block wall, it should be backfilled with tightly packed mortar by the brick/block layer. Alternatively, the frame can be fixed into place with expanding masonry anchors and then the mortar/cement/grout mix used to backfill the frame. Maximum of 4-hour rating.

➢ Fire Rated Plasterboard

When afire door frame is built into a plasterboard wall, it should be backfilled with fire rated plasterboard strips prior to installing into the wall. The consists of cutting and fitting strips of fire rated plasterboard to the inside of the frame and adhering them in place using a standard plaster based jointing compound. Unfortunately, it is not possible to fill frames in plaster walls post installation. Maximum of 4-hour rating.

➢ Powers Fire Foam

Can be used post-installation using holes drilled in frames. Maximum of 2-hour rating.

➢ CSR Bradford Rockwool

Can be used as a filling medium and fitted pre-installation. Maximum of 1 hour rating.

➢ Vermiduct Spray

Can be used as a filling medium and fitted pre-installation. Maximum of 2-hour rating. In all cases it is imperative that the backfilling medium is tightly packed, and all available airspace is removed. Finally, the finished backfilled frame must be tightly sealed against the surrounding opening it is being fitted to using an approved fire rated sealant.

Fixing Methods & Designs

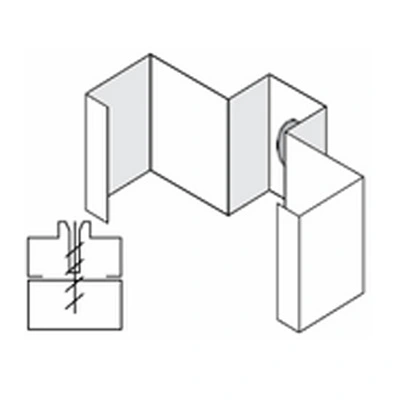

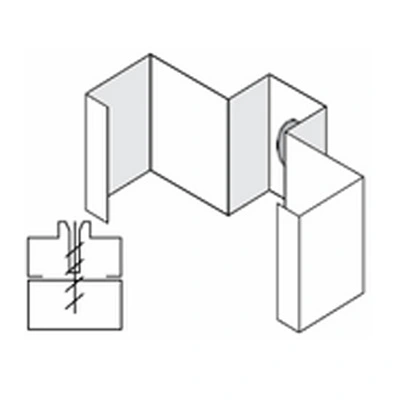

Fast-Fix Bracket (also referred to as stud-fix bracket)

The most popular fixing method, Fast-fix brackets are welded into the back of the door frame stiles for fixing to the opening by screwing from the wall stud frame through into the brackets. The brackets are designed to fit screws of 10 gauge or larger, long enough to fix through the stud and into the Fast-fix brackets. Fast-fix brackets are manufactured to suit your wall thickness and wall linings thickness, or multiple wall linings.

Tube Fixing

Tube fixings consist of a 10mm countersunk hole, usually placed in the door stop and are backed by welded tubes on the inside of the frame stiles and head. The tubes protect the fixing hole from being blocked during the back filling of the frame (required for fire rated applications) and provides a guide to ensure the fixings are driven in straight ensuring the frame does not twist during installation. Typical fasteners used with tube fixing are dynabolts or concrete screws.

Screw Fixing

Screw fix is suitable for any wall application where one of the recommended preceding fixing methods are not achievable.

A screw fixing is a 5mm or 10mm countersunk hole usually placed in the frame door stop for fastening the frame to the wall aperture.

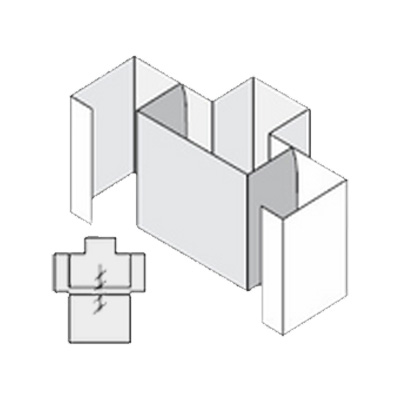

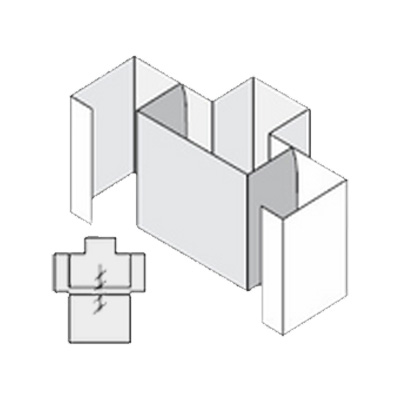

Split-frame Fixing

The split frame profile is available for FRL-/60/30 only. The two frame halves are fixed together through the door stop and provides a solution where a one-piece frame cannot be practically installed. The inside frame also acts as a trimming providing a neat finish.

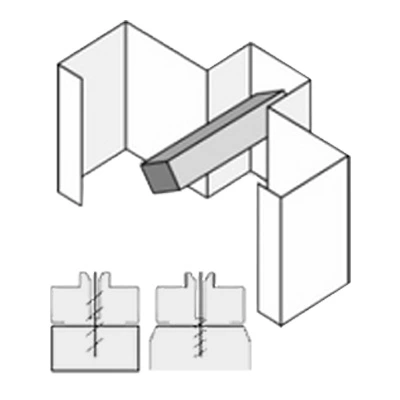

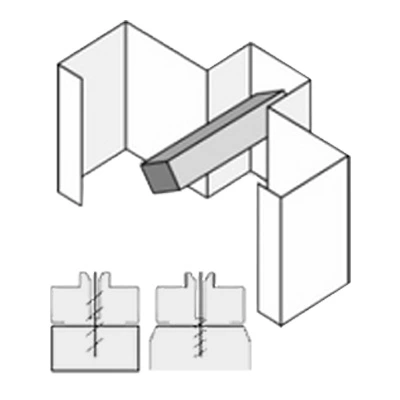

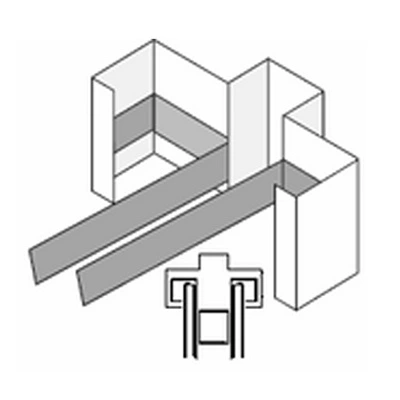

Tube Fixing with Anti-flex Straps

This fixing is as described above with additional anti-flex straps. Anti-flex straps are welded across the frame throat in line with the tube fixings which are designed to prevent the frame from twisting during installation.

Anti-flex straps – Pre-cast Concrete

Doorframes can be manufactured with anti-flex straps only which are typically required for precast concrete application. The straps are placed and welded across the frame throat and will prevent the frame from twisting during the concrete pouring process.

Material Type and Gauge

– 1.1mm Galvanneal (FRL-/60/30 split frames only)

– 1.5mm Galvanneal

– 1.6mm Galvanised

– 1.5mm 304 grade Stainless Steel

Finishes

– Fully welded and primed

– Stainless steel – welded & primed

– Powder-coated

– Sentry Protect powder-coat for corrosive environments

Accessories

– Standard strikers

– Electric strikers

– 100×75 hinge backing plates

– 100x75x2.5mm Stainless Steel Butt Hinges

– 100×100 hinge backing plates

– 100x100x2.5mmStainless Steel Butt Hinges

– Pivot hinge prep

– Door closer reinforcement

– Pivot hinge reinforcement

– M5 hinge screws

Frame Profile Terminology

– Throat

– Returns

– Architraves

– Rebates

– Door stops

– Reveal width

– Reveal height

– Striker height

Non-rated Steel Door Frames

Non-rated steel door frames offer a durable and versatile solution for a wide range of applications. Designed for strength and longevity, they provide a clean, professional finish while allowing flexibility in installation.

Choose your wall type, fixing method, material, and finish to ensure the perfect fit for your project. With multiple configurations available, our frames can be tailored to suit various construction needs, from commercial and industrial buildings to residential projects.

Wall types

- Masonry

- Brick and block walls

- Steel & timber stud walls

- Plasterboard

- Partitions

Fixing Methods & Designs

New Generation

The New Generation profile incorporates built in plaster grooves on either side of the profile with concealed fixing holes which allows you to conveniently hide your fixing behind your plaster sheet and minimises plaster finishing. The grooves can be customised to suit your specific plaster/cladding thickness.

Fast-Fix Bracket (also referred to as stud-fix bracket)

The most popular fixing method, Fast-fix brackets are welded into the back of the door frame stiles for fixing to the opening by screwing from the wall stud frame through into the brackets. The brackets are designed to fit screws of 10 gauge or larger, long enough to fix through the stud and into the Fast-fix brackets. Fast-fix brackets are manufactured to suit your wall thickness and wall linings thickness, or multiple wall linings.

Tube Fixing

Tube fixings consist of a 10mm countersunk hole, usually placed in the door stop and are backed by welded tubes on the inside of the frame stiles and head. The tubes protect the fixing hole from being blocked during the back filling of the frame (required for fire rated applications) and provides a guide to ensure the fixings are driven in straight ensuring the frame does not twist during installation. Typical fasteners used with tube fixing are dynabolts or concrete screws.

Screw Fixing

Screw fix is suitable for any wall application where one of the recommended preceding fixing methods are not achievable.

A screw fixing is a 5mm or 10mm countersunk hole usually placed in the frame door stop for fastening the frame to the wall aperture.

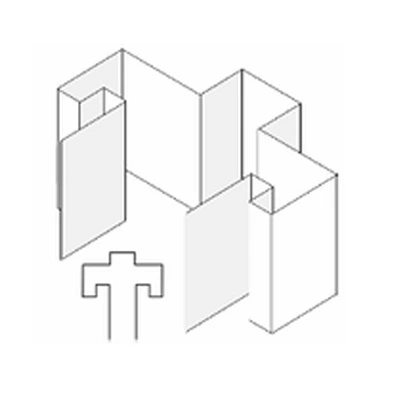

Stud Clips

Stud clips are designed to clip into the back of the frame for anchoring on the wall stud. The stud clip is sized to accommodate the thickness of the wall sheeting to allow sufficient space between the wall and channel and the frame return allowing the wall sheeting to be slid into the back of the frame.

Stud clips come in standard sizes of 10mm, 13mm, and 16mm, supplied loose in a standard pack of 16. Stud clips are not suitable for retrofit or single rebated jambs.

Split-frame Fixing

The split frame profile is ideal as a retrofit solution. The two frame halves are fixed together through the doorstop and provides a solution where a one-piece frame cannot be practically installed. The inside frame also acts as a trimming providing a neat finish.

Tube Fixing with Anti-flex Straps

This fixing is as described above with additional anti-flex straps. Anti-flex straps are welded across the frame throat in line with the tube fixings which are designed to prevent the frame from twisting during installation.

Anti-flex straps – Pre-cast Concrete

Doorframes can be manufactured with anti-flex straps only which are typically required for precast concrete application. The straps are placed and welded across the frame throat and will prevent the frame from twisting during the concrete pouring process.

Partition

A partition fixing is designed to fit neatly over any partition or stud wall concept. It incorporates larger return folds back from the frame throat that are to be fixed through into the wall aperture.

Wire Ties

Wire ties are commonly used in brick wall application. They are provided loose in packs in quantities depending on the frame height. The frame is positioned in place and wire ties are located between bricks as the brick wall is being built up.

Material Type and Gauge

– 1.1mm Galvanneal

– 1.5mm Galvanneal

– 1.6mm Galvanised

– 1.2 & 1.5mm 304 grade Stainless Steel

– 1.2mm 316 grade Stainless Steel

Finishes

– Knock-down and primed

– Welded and primed

– Stainless steel – welded & primed

– Powder-coated

– Sentry Protect powder-coat for corrosive environments

Accessories

– Standard strikers

– Electric strikers

– 100×75 hinge backing plates

– 100x75x2.5mm Stainless Steel Butt Hinges

– 100×100 hinge backing plates

– 100x100x2.5mmStainless Steel Butt Hinges

– Pivot hinge prep

– Door closer reinforcement

– Pivot hinge reinforcement

– M5 hinge screws

Frame Profile Terminology

– Throat

– Returns

– Architraves

– Rebates

– Door stops

– Reveal width

– Reveal height

– Striker height

Why choose Larnec?

Advanced materials and construction

Our products are made from high-quality materials, ensuring durability and reliability. They feature a range of fire-rated seals, hardware, and frames designed to meet stringent safety standards. Choose from our extensive selection to find the perfect solution for your specific requirements.

Custom steel door frame options

Custom Steel Door Frames are built to meet unique project specifications.

Versatile Design

Manufactured in Australia

All our doors are manufactured in our Australian facilities to the highest quality standards. You can expect a consistent result every time.

Buy your Steel Door Frames in 4 steps

1

Get free advice

Talk to our team about your business needs and we’ll recommend the right door solutions.

2

Order confirmation

We organise the contracts for your order and schedule your doors for production.

3

Manufacturing

We manufacture your doors in our Australian facilities using the Toyota Production System.

4

Delivery

Our national network will deliver to site, store, or consolidation centres around the country.

Download brochures and specifications for all our doors

Get all the details you need to specify Larnec for your next project.

- Product Technical Data Sheets

- Detailed technical drawings

- Installation guides

You don’t cut corners. Neither do we.

For expert advice on the safest doors for your needs, book a quick consultation with our steel door frames specialists for free.